- Welcome to Hi -Ji Metal company

-

Send Your Mail At

info@hijimetal.com

-

Phone no.

+91 9022 304 316

-

Working Hours

Mon-Sat:9.30am To 7.00pm

Stainless Steel

WireMesh

Grades of Stainless Steel Wire

| Stainless Steel Wire Mesh Size | Stainless Steel Wire Gauge Diameter | ||

|---|---|---|---|

| Sizes in mm | In Inch | BWG No. | Sizes in mm |

| 6.4 | 1/4 | BWG24-22 | 0.56- 0.71 |

| 9.5 | 3/8 | BWG23-19 | 0.64 - 1.07 |

| 12.7 | 1/2 | BWG22-16 | 0.71 - 1.65 |

| 15.9 | 5/8 | BWG21-16 | 0.81 - 1.65 |

| 19.1 | 3/4 | BWG21-16 | 0.81 - 1.65 |

| 25.4x 12.7 | 1 x 1/2 | BWG21-16 | 0.81 - 1.65 |

| 25.4 | 1 | BWG21-14 | 0.81 - 2.11 |

| 38.1 | 1 1/2 | BWG19-14 | 1.07 - 2.11 |

| 25.4 x 50.8 | 1 x 2 | BWG17-14 | 1.47 - 2.11 |

| 50.8 | 2 | BWG16-12 | 1.65 - 2.77 |

| 50.8 to 305 | 2 to 12 | At Request | |

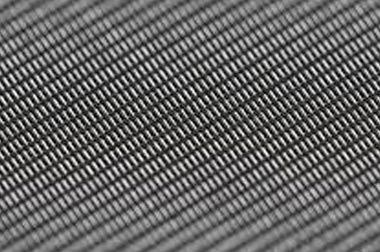

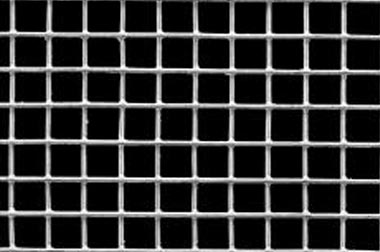

SQUARE MESH / FINE MESH

The most commonly used weave. Openings are square. Each weft wire passes alternately over and under each warp wire and vice versa. Warp and weft wire diameters are generally the same. It produces screens with the same mesh count in both directions.

Plain weave meshes are available with apertures from 10.7mm (2 mesh) to 0.05mm (325 mesh). Suitable for many commercial applications.

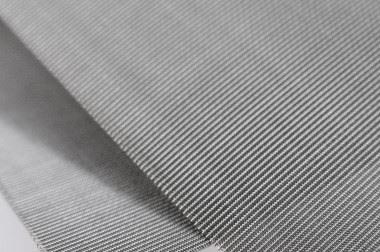

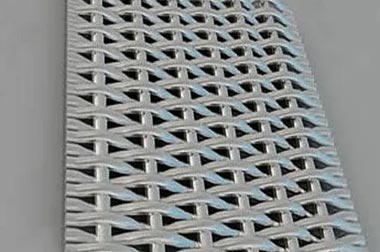

TWILL WEAVE (TW)

Twill weave can be made from larger diameter wires than would be possible in plain square weave to obtain greater strength, density, or corrosion resistance. This weave is stronger than plain weave. Each weft wire alternately crosses over two, then under two, warp wires producing a diagonal pattern. The wire diameter for both warp and weft is normally the same.

Twill weave is usually used to accommodate a heavier than standard wire diameter in association with a given mesh.

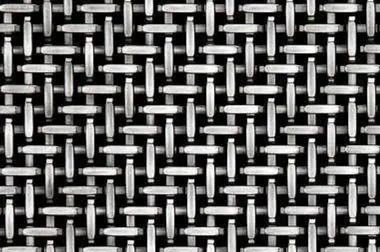

PLAIN DUTCH WEAVE WIRE MESH (PDW)

Woven in an over and under pattern, but warp wires are heavier — larger in diameter — than shute wires which are driven very close to create a high density wire mesh with much lower flow rates and much higher particle retention than plain square weaves

TWILL DUTCH WEAVE WIRE MESH (TDW)

Similar to Plain Dutch except woven in the Twill Style. Each wire passes over two wires then under two wires, still utilizing a smaller-diameter shute wire, allowing an even tighter weave and even finer filtration than Plain Dutch Weave.

REVERSE TWILL DUTCH WEAVE (RTDW)

Reverse Dutch Weave is produced by the use of coarse mesh (mesh wire, woven wire mesh) in the warp and a fine mesh with relatively smaller wire in the fill. This weave results in greater strength with very fine openings and is primarily used as a filter cloth. The shape and position of the openings aid particle retention and increase filter cake formation.

HOLLANDER WEAVE

A plain weave with the warp wires of a larger diameter than the weft. The weave is made up of a limited number of warp wires interwoven with the maximum number of weft wires which can be knocked up. The cloth is strong and firm and is most frequently used for high pressure filtration.